The market development trend of power electronics industry puts forward requirements for the application of special components.The same is true for current measurements.Basically speaking, in order to obtain a certain measurement accuracy, it requires that the components have the corresponding size and the corresponding cost.This paper introduces a new generation of current sensor, which can improve the performance of current sensor based on open loop hall effect by a specially developed ASIC technology.

At present, we can purchase many hall -ASIC sensors in the market, we can use these sensors to measure the position, magnetic field and current.All these ASIC sensors are mostly used for accurate and rapid current measurement, such as power electronics industry, and have the advantages of high anti-interference for electromagnetic interference.This foundation has led to the development of new integrated components that are particularly suited to these requirements (figure 1).Based on CMOS technology, the new integrated component integrates all the components of the open-loop hall effect current sensor structure into a single chip.The hall array ACTS as a measuring element, followed by an amplifier stage and an extended programming unit and a stable bandgap reference voltage.

The component has the following characteristics:

5 v power supply

A large measurement range from 0.5 to 4 millivolts/gauss

Bias and gain can be programmed (proportional or fixed)

Benchmark input/output

Programmable temperature compensation

Terminal pin has short circuit and ESD protection

Temperature ranges from - 40 ° C to + 125 ° C.

The reference voltage as the zero of the measurement can be programmed in the production process.Can provide half of the supply voltage or fixed 2.5v voltage.Reference voltage can also be provided on the external pins.For example, the reference voltage can through A current external from the A/D converter reference voltage by A 200 Ω internal load impedance function.

parameter

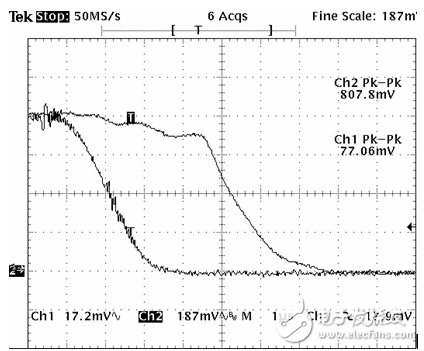

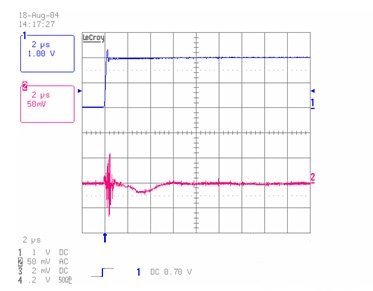

Compared with the traditional hall element, the velocity of the transient current is almost unchanged.The delay time after the transient current with 100A/ * s current change rate (di/dt) is about 4 s, as shown in figure 2.This delay time should be sufficient for short-circuit cutoff and regulation of the current circuit.The slightly longer delay time can be illustrated by hall chip chopper technology, which is used to improve drift parameters.

For sensors used in high EMC environments, one of the key parameters is the performance after the voltage jump (common mode).Figure 3 records the 6 KV/ * s current rate of change (dV/dt), and gives the state after skipping a deviation when the output is about 20mV, which is consistent with the drift of 3% nominal value.Performance is balanced, so it can be filtered externally or internally without bias.

Because of the stability of the chopper, the noise at the sensor output is three times greater than that of a conventional hall element.In general, this noise is approximately 10m/Vpp, corresponding to approximately 1.4% of the output nominal current.Due to the high noise frequency of 500KHz, this noise does not affect normal applications.This parameter should be taken into account for ultra-fast current regulation circuits with high bandwidth.

In terms of temperature drift, which is the most basic parameter for current sensors, the maximum improvement can be achieved by comparing with traditional solutions.Compared with traditional sensors, the deviation drift and gain drift have been improved by a factor of more than 2.When the temperature rises 50 ° C, the maximum deviation drift, 1.6% maximum nominal value.Gain drift, defined as the percentage of the measured value, can reach 2% at worst.These values are excellent for the open-loop hall effect current sensor.

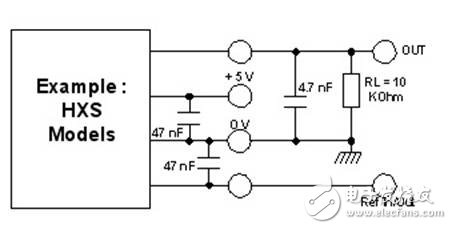

Sensors mounted on printed circuit boards shall be as closely connected to the decoupling capacitance as possible.These capacitors can significantly improve EMC characteristics.Figure 4 shows the wiring diagram, which has the values actually found in the measurement process.However, this wiring will vary slightly depending on the application.

The reference voltage shall have the same value as the supply voltage.

Various applicable design schemes

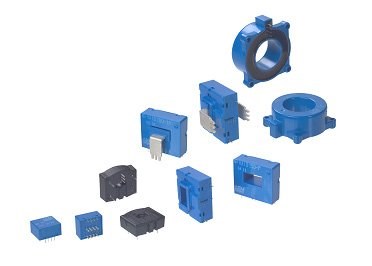

With this ASIC technology, we have developed four new models of open-loop hall effect current sensors in a range of applications.During the development of the sensor, particular attention was paid to the requirements of the applications covered, the mechanical aspects and the separation and insulation of the electrical and electronic components.For example, in battery-powered vehicles, we have also developed for the first time a special sensor for low voltage applications up to 100V.

HXS

Minimum design for measuring current from a nominal value of 50A to a measurement range of 150A.The sensor has four main main lines, which can be connected in parallel or in series, and enables the element to cover three measuring ranges.

The model range includes six different sensors for various applications, which differ in the current range, various temperature ranges, and core materials.In particular, a sensor for long shielded conductors and capacitive currents associated with these conductors has been developed.Therefore, the core heating caused by high frequency loss is eliminated.The sensor is particularly suitable for frequency converters, power supplies and small UPS devices.

HAIS

This model covers a current range of 50-400a (600A).Meet the requirements for safe operation at a nominal voltage of up to 600V (overvoltage class III, pollution level 2).The main opening can accommodate a total line with a cross section of up to 15 x 8 mm.For mounting to PCB, two additional solder pins are provided, which can also be used to improve EMC characteristics when grounding.

HTFS

With a 22mm opening, the sensor is suitable for cables and general wiring.It may also provide a measurement range of up to 1,200 a.The sensor has extremely stable mechanical properties and can be attached to a printed circuit board with solder pins or screws.The sensor is particularly suitable for battery-powered vehicles such as forklifts or hybrid excavators.For the first time, it is possible to record currents exceeding 1000A through the miniature design.

HFIS

Since the current current sensors are used in various automotive applications, these sensors have been further used in industrial applications.In order to achieve compact design, the main opening is set very small.Therefore, this type of sensor is mainly suitable for various applications with low constant current and high measurement range.Moreover, this type of sensor meets a safety isolation requirement of only up to 100V.Applications include switching networks with low peak currents and battery-powered vehicle components such as wheelchairs and golf clubs.

conclusion

According to the application requirements, we provide customers with several design models.Since only a single component is used, one thing these design models have in common is a high working utilization with good mean time between failures (MTBF).Six sigma tools were used in the development process to eliminate error sources that might eventually have existed in production.

According to European EMC standard, all components have EC identification and safety isolation.All types of sensors will be UL certified.All sensors comply with the European RoHS directive effective 1 July 2006.

Inglés

Inglés  Chino

Chino  Alemán

Alemán  Coreano

Coreano  Japonés

Japonés  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  Español

Español