Power system design engineers are facing greater challenges than ever before.More sophisticated sensing algorithms, the latest energy efficiency challenges and the application of a new generation of advanced sensors mean that power designers need to learn a wider range of skills than ever before, while constantly absorbing new design ideas and solutions, in order to gain a foothold in the power market.

Some of these challenges are driven by existing technologies: as components become more complex, engineers need more specialized knowledge to optimize their applications.But greater pressure comes from the different needs of various applications, particularly the need for energy efficiency or "green" design.A typical case is household appliances, such as washing machines, which are required by users to be efficient and easy to operate. This has prompted manufacturers to adopt new motor control technology, which has led to the development and application of new components.This dramatic change means that electrical engineers must constantly update their expertise.

Sensor (transducers), for example, a single sensor function of the past will be onboard signal processing and control algorithm of sensor is replaced.HansDieterHuber, vice President of the lyme electronics industry, said, "there are two driving forces driving the latest advances in sensors today. One is the need for comfort.Another is to save energy demand, this requirement means that more and more used to use the mechanical control applications will change the perfect electronic control, thus provide higher reliability, control function and the improvement of higher energy efficiency, for example, is now only 15% of the motor with frequency conversion control, and the full electronic control can save 50% of the total energy consumed, achieve significant energy savings."

Technological progress drives engineers to improve their design skills, and in turn, customer demand drives technological progress.According to HansDieterHuber, LEM is working closely with power designers in various markets, including industry, public transportation, energy and automation, and the automotive market. For designers in almost all of these areas, the most significant trend for next-generation motor control is miniaturization, high efficiency, and high performance.HansDieterHuber said: "our customers are demanding the best solution to enable accurate measurements of the current in their applications.They also expect current measurement solutions that will add value to the final application, allowing it to differentiate itself from the competition.This requires the smallest sensor to provide the best accuracy performance and be able to easily integrate and communicate with other existing electronic components such as microcontrollers.LEM also works closely with customers to improve the product, which will enable even greater breakthroughs in the existing performance parameters of current and voltage sensing for power applications.These breakthroughs will form the basis on which designers can make their products more efficient and functional.

LEM began to integrate asics into the sensor eight years ago, a move that enabled the development of the IP and the current Minisens series of sensors to enable such applications as energy-efficient household appliances.Integrated circuits allow for small sizes and high precision at competitive prices, and these sensors help designers continue their push toward miniaturization."We've developed a mature current sensor that integrates the magneticconcentrator into a so-8 concentrator," HansDieterHuber said.This very small device, called the Minisens, provides a standard solution for dc and isolated current measurements in situations where previous measurements could not be made or shunt measurements were used.Designed entirely by our company, the ASIC is particularly suitable for current measurement and improves electrical performance, such as compensating for errors caused by thermal drift.We are also able to offer new improvements that are not part of the usual current measurement methods, such as short circuit detection or faster output in standby mode, and we have made great progress in terms of integration and size reduction.

Since these devices are packaged in a standard chipset, it is convenient to use this chip in the PCB surface mount process.

As the skills required for efficient power design broaden, the ability to master specialized knowledge becomes critical.Through close partnerships with customers around the world, LEM believes it is the sharing of current and voltage measurements that has earned it market leadership for more than 37 years.LEM offers a detailed understanding of the specific requirements of each market and each application, and the ability to quickly develop new products that combine on-site quality verification and novel design features.In this way, LEM can provide power designers with standard and customized products that are completely suitable for various applications.

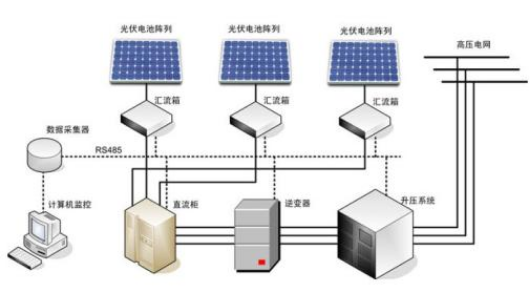

It is worth mentioning that another important challenge facing all enterprises is the current economic situation.While it may take years for the overall market to fully recover, renewable energy will most likely rebound faster than other sectors.Governments are investing heavily to speed up the rebound and make power designs look promising."Green" products are likely to be the main beneficiaries of government support, and technologies such as cutting energy consumption through cutting-edge power designs or generating electricity from renewable sources will require government investment in many countries.

The integration of more advanced current and voltage measuring devices, the increasing demand for digital design for intelligent motor control, and the enormous potential of renewable energy present an attractive and challenging future for power designers.

Inglés

Inglés  Chino

Chino  Alemán

Alemán  Coreano

Coreano  Japonés

Japonés  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  Español

Español