Integrated circuit, commonly known as chip.A microelectronic device or component.Using a process to connect the required transistors, resistors, capacitors and inductors of a circuit to the wiring.Made on a small piece or pieces of semiconductor chip or dielectric substrate, and then encapsulated in a shell, to become a required circuit function of the micro structure.All the components have formed a whole in structure, which makes electronic components take a big step towards miniaturization, low energy consumption, intelligence and high reliability.

The Integrated Circuit (IC) plants in the world are mainly distributed in a few developed countries and regions such as the United States, Japan, Western Europe, Singapore and Taiwan, among which Taiwan plays a decisive role.In recent years, however, a series of events, such as earthquakes, financial crisis and government change, have made the island, which is short of resources, small in market and popular among people, more unstable. This has triggered a wave of fab relocation.The mainland, with its vast territory, abundant resources, huge potential market, abundant supply of human resources and other advantages, of course has become the preferred place to move to.

Fabs actually make two major parts of the product: wafers, or wafers for short, and vlsi chips, or chips for short.The former is a smooth, round, mirror-like sheet of material that, strictly speaking, has no practical application but is used as the raw material for further processing in subsequent chip-making processes.While the latter is the final product directly applied in many industries such as computer, electronics and communication, it can include CPU, memory unit and various other professional application chips.

What is the process of making an integrated circuit board?

1. Printed circuit board.Print the printed circuit board with transfer paper, pay attention to the slippery side facing yourself, generally print two circuit boards, namely print two circuit boards on one piece of paper.Choose one of the printed circuit board produced very good results.

2. Cut out copper clad plate and use photographic plate to make circuit board diagram.Copper clad board, i.e. circuit board with copper film on both sides, cut copper clad board into size of circuit board, not too large, to save materials.

3. Pretreatment of copper clad plate.Use fine sandpaper to polish off the oxide layer on the surface of the copper clad plate to ensure that the carbon powder on the thermal transfer paper can be firmly printed on the copper clad plate when the printed circuit board is transferred. The polished standard is the bright surface without obvious stains.

4. Transfer printed circuit board.Cut the printed circuit board to a suitable size and stick the printed circuit board side on the copper clad plate

Wafer production process:

In a larger sense, wafer manufacturing consists of two major steps: wafer fabrication and wafer fabrication. It can be subdivided into the following major steps (wafer fabrication consists of only the first step and the rest of the steps are wafer fabrication) :

Polycrystalline silicon, monocrystalline silicon, silicon rods growth - crystal bar cutting and grinding - section - round edge detection - diameter, surface polishing, etching, defects - - (denotation, etching, defects) - cleaning - inspection - packaging: 1, crystal rods growth process it can be subdivided into:

Melt (Melt Down) : 1), a block of high purity polysilicon in the quartz crucible, heated to its melting point 1420 ℃ above, make its Melt completely.

2) Neck Growth: after the temperature of the fused silica slurry is stabilized, seeds in the direction of < 1.0.0 > are inserted into it slowly, and then the seeds are gradually increased to reduce their diameter to a certain size (generally about 6mm), maintain the true diameter and lengthen by 100--200mm to eliminate the differences in grain alignment within the seeds.

3) Crown Growth: after the neck Growth is completed, slowly reduce the lifting speed and temperature, and gradually increase the neck diameter to the required size (e.g., 5, 6, 8, 12).

4) Body Growth: keep adjusting the lifting speed and melting temperature, and maintain a fixed diameter of crystal rod until the length of crystal rod reaches a predetermined value.

5) Tail Growth: when the length of the crystal rod reaches the predetermined value, it will gradually accelerate the lifting speed and increase the melting temperature, so that the diameter of the crystal rod will gradually become smaller, so as to avoid the phenomenon of displacement and slip caused by thermal stress, and eventually the crystal rod will be completely separated from the liquid level.You get a complete crystal rod.

2. Cutting & InspecTIon: remove the head and tail parts with small diameter from the growing crystal bar, and test the size to determine the processing parameters for the next step.

3. Surface Grinding & Shaping: in the growth process of crystal rod, its outer diameter and roundness are all biased to some extent, and its outer cylindrical Surface is also uneven. Therefore, it is necessary to repair and grind the outer diameter to make its size and shape error less than the allowable deviation.

4. Wire Saw Slicing: because the hardness of silicon is very large, in this order, the crystal bar is cut into thin slices with a circular Saw blade with diamond particles embedded in the edge of its inner diameter.

5. Edge profiling: due to the sharp outer Edge of the freshly cut wafer and the brittleness of monocrystalline silicon, in order to avoid the impact of Edge crack on the wafer strength, damage to the surface smoothness of the wafer and contamination of the particles caused by the following processes, the Edge shape and outer diameter size of the wafer must be automatically trimmed by special computer control equipment.

6. Lapping: the purpose of Lapping is to remove the saw marks and damages on the wafer surface during cutting, so as to achieve the required surface finish.

7. Etching: the process of chemical Etching to remove a layer of damage on the surface of the wafer caused by processing pressure after several processes.

8. Gettering: to use sand blasting to drive the flaws and defects on the wafer to the lower half layer for subsequent processing.

9. Polinshing: the process of polishing the edges and surface of the wafer to further remove the particles attached to the wafer and to obtain excellent surface flatness for the wafer processing process to be discussed later.

10.Cleaning: clean and air dry the finished chip.

11. IinspecTIon: the final and comprehensive inspection shall be carried out to ensure that the product finally meets the specified technical specifications such as size, shape, surface finish and flatness.

12.Separate, pack and pack the products with flexible materials, ready to be sent to the chip manufacturing workshop or the factory for ordering customers.

Chip production process:

The manufacturing process of chips can be generally divided into several steps, such as Wafer FabricaTIon, Wafer Probe, Packaging and IniTIal Test and Final Test.Among them, the wafer processing process and wafer needle measurement process are the Front End process, while the assembling process and testing process are the Back End process.

1, wafer processing, the main work of this process is making the circuit on the wafer and electronic components such as transistors, capacitors, logical switch, etc.), the handler is often associated with products and the technology used, but the general basic steps is to wafer appropriate to clean first, again on the surface of oxidation and chemical vapor deposition, then coating, exposure, development and etching, ion implantation, metal sputtering step repeatedly, eventually completed several layers of circuit on the wafer and components processing production.

2. Wafer needle testing procedure: after the previous procedure, a small lattice is formed on the wafer, namely grain. Generally, products of the same variety and specification are made on the same wafer for the convenience of testing and efficiency improvement.But also according to the need to produce several different varieties, specifications of products.After the electrical characteristics of each grain were detected with a Probe instrument and the unqualified grains were marked, the wafer was cut into individual grains and then classified according to their electrical characteristics and put into different pallets. The unqualified grains were discarded.

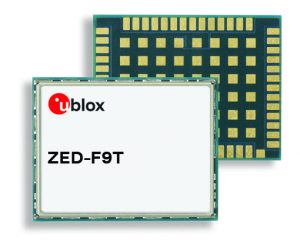

3. Assembly process: fix a single grain on the base of a plastic or ceramic chip, and connect some of the lead ends on the grain to the pins protruding from the bottom of the base for connecting with the external circuit board. Finally, cover the plastic cover and seal it with glue.The purpose is to protect the grain from mechanical scratches or high temperature damage.That's when you make an integrated circuit chip (that's the black or brown rectangle we see on a computer with lots of pins and leads on either side or side).

4. Test procedure: the last procedure of chip manufacturing is test, which can be divided into general test and special test. The former is to test the electrical characteristics of the sealed chip under various environments, such as power consumption, speed and pressure resistance.The tested chip is classified into different grades according to its electrical characteristics.And special test, it is according to the technical parameter of customer special demand, take out a part of chip from close parameter specification, breed, do specific and specific test, see whether can satisfy the special demand of the customer, in order to decide whether to must design special chip for the customer.The products which have passed the general test can leave the factory only after they are labeled with specifications, models and date of manufacture.Chips that fail the test are rated as degraded or rejected depending on the parameters they achieve.

Inglés

Inglés  Chino

Chino  Alemán

Alemán  Coreano

Coreano  Japonés

Japonés  Farsi

Farsi  Portuguese

Portuguese  Russian

Russian  Español

Español